Money

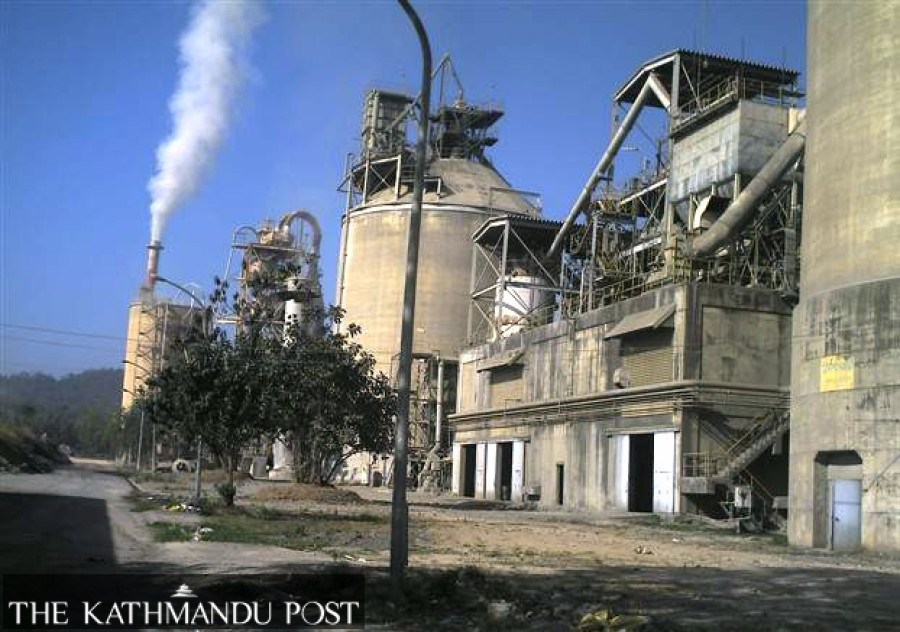

Udayapur Cement seeks Rs500 million loan to replace obsolete equipment

The factory has a production capacity of 800 tonnes daily, but it cannot run at full capacity because of old machinery.

Krishana Prasain & Dilliram Khatiwada

State-owned Udayapur Cement Industry has asked the government for a Rs500 million loan investment to ramp up production by replacing obsolete equipment, but the proposal has been gathering dust at the Ministry of Finance for more than a year.

“The Finance Ministry has been saying that it will approve the plan, but a year has passed and there has been no decision,” said General Manager Gopi Krishna Neupane. “We do not know why the paperwork is stuck at the ministry.”

The factory has a production capacity of 800 tonnes daily, but it cannot run at full capacity because of old machinery, officials said.

Presenting the budget statement for the current fiscal year, Finance Minister Janardan Sharma said that the budget had emphasised increasing industrial output.

"The budget has prioritised increasing domestic production and consumption amid fast-rising imports, shrinking exports and falling output," Sharma said in a post-budget statement.

"But looking at the way things are moving, the government's pledge seems to have been talk only," Neupane said.

The budget for the current fiscal year said that the need and justification for public enterprises besides their economic and financial aspects would be examined thoroughly to determine whether to keep running them in the existing format, restructure them, remove them from government ownership or shut them down.

The budget statement also said that the necessary arrangements would be made to operate state-owned cement plants with export potential at full capacity.

“We are not getting support as stated in the budget,” Neupane said. "The government is busy with preparations for the general elections, and this might be the reason why our concerns are not being addressed."

Ramesh Kumar KC, joint secretary of the Finance Ministry, said the budget for the current fiscal year had not allocated funds for Udayapur Cement Industry under any heading. "If funding has not been set aside in the budget, it cannot be made available from other sources," he said.

“The Financial Sector Management and Corporation Coordination Division has forwarded the file with a favourable recommendation. But the coordination of the budget division and other divisions in the ministry is needed,” KC said.

"We need to analyse the appropriateness of the investment, the profit and loss status, and the advantages and disadvantages before committing funds," he said.

A Finance Ministry official said the absence of a budget allocation and all the calculations being made may have slowed down the file.

Udayapur Cement Industry has 300 permanent employees and 146 local workers.

“The government is not putting money in the productive sector but spending it in the unproductive sector,” Neupane said.

The loan investment proposal had been instantly approved by the Industry Ministry but got bogged down in the Finance Ministry. The Finance and Industry ministries are the share-owners of the company.

“We will turn the factory into a profit-making enterprise if the additional investment is provided. We have a huge scope of exporting cement to Uttar Pradesh and Bihar states of India; and with the additional investment, we will be able to do that too,” Neupane said.

"The limestone the factory is using is of high quality, and it is not available in other parts of the country. But we need to replace the old machines with new ones. Replacing old equipment will slash coal consumption by 25 percent, which is one of our major expenses," he said.

“We used to produce around 5,000 sacks of clinker daily, but now we are churning out around 8,000 sacks after tuning up the machinery,” Neupane said.

The plant was installed 33 years ago, and most of the technology has become obsolete while private cement factories have been using the latest equipment.

The factory located in eastern Nepal is producing high-grade quality, Gaida brand cement using high-quality limestone. The factory sold 2.17 million bags of cement in the last fiscal year and is targeting to sell 2.5 million bags in the current fiscal year.

In order to achieve the target, production needs to be increased by 41 percent. And to increase the capacity, new equipment has to be brought in, the administration said.

The factory is still running age-old machines, which prevents it from producing clinker as per demand.

"The company management has requested the government for a loan investment along with the estimated value of the new machines by conducting a technical study," Neupane said.

Neupane said that they had sent the proposal with a pledge to pay back the loan within three years with interest to the Finance Ministry along with the Industry Ministry's recommendation.

“We might need to pay Rs1 billion in retirement benefits to our staff, and if we get the extra investment, we will be able to make this payment. We will take the factory into profit,” Neupane said.

Udayapur Cement Industry, which broke even last year, is going through hard times because of soaring prices of diesel, coal and raw materials.

Due to an increase in the service facilities of its employees, there are chances the company will go into the red again. To prevent such a situation from occurring, there is a need to increase the capital, officials said.

Neupane said that extra investment must be made to reduce down time, increase production and reduce the consumption of coal by installing new technology.

"As most of the employees will be retiring in around five years, the government will be able to fulfil its responsibility of providing benefits to the staff that may amount to billions only if the capacity of the factory is expanded. If not, we will have to run to the Ministry of Finance for money," said Pokharel, spokesperson for the company.

The factory reopened in January 2020 with the arrival of Neupane after sorting out raw material and other problems.

"As of September 2021, the retired employees had received a sum of Rs150 million. In the fiscal year 2020-21, the company made a profit of Rs560 million after deducting a loss of Rs5.55 billion," Neupane said.

"The company has completed an organisation and management survey, a general meeting after a gap of 15 years, plant maintenance and internal and external audits besides updating the records at the Company Registrar's Office which has not been done since the establishment of the company," he said. "From the perspective of governance, these tasks are important."

Udayapur Cement Industry suffered a loss of Rs300 million in the fiscal year 2020-21. But in fiscal 2021-22, expenditure was slashed and the company became profitable after many years.

Recently, the general manager discussed a memorandum submitted by the active trade unions in the company which included a demand to ensure regular operation of the plant.

Pokharel says that the industry has been operating regularly since October 16 after the Dashain holidays by completing maintenance work.

Nepal is estimated to require 25.88 million tonnes of cement annually by 2024-25 due to an investment push in mega infrastructure projects, a study on the socio-economic impact of foreign direct investment in the country's cement industry published by Nepal Rastra Bank shows.

In 2019, the Ministry of Industry had projected that the installed capacity of Nepal's cement industry could increase to 20 million tonnes by the end of 2023-24, from 15 million tonnes currently.

According to the report, the actual annual production before the Covid-19 pandemic was recorded at around 7.5 million tonnes, although the installed capacity is 15 million tonnes.

Domestic consumption amounts to 9.05 million tonnes, and the shortfall is covered by imports. In 2018-19, according to the report, 1.56 million tonnes of cement was imported from India.

The report said that most of the mega projects in Nepal use cement imported from India due to issues of certification, quality consistency and inability to provide bulk supply.

The survey was conducted in seven cement factories—three-run by foreign investors, two state-owned and two private sector-run factories—among the 55 plants currently in operation in the country.

13.12°C Kathmandu

13.12°C Kathmandu